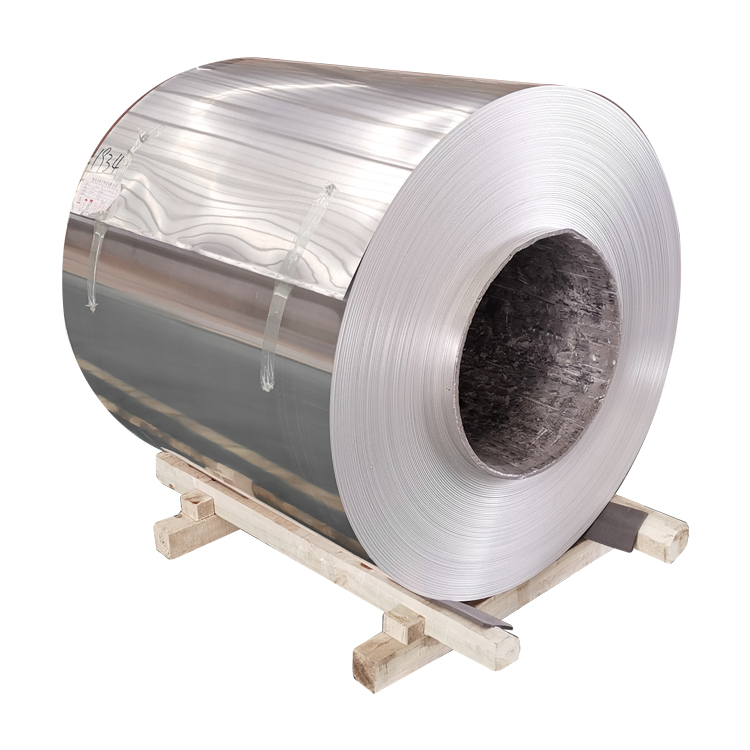

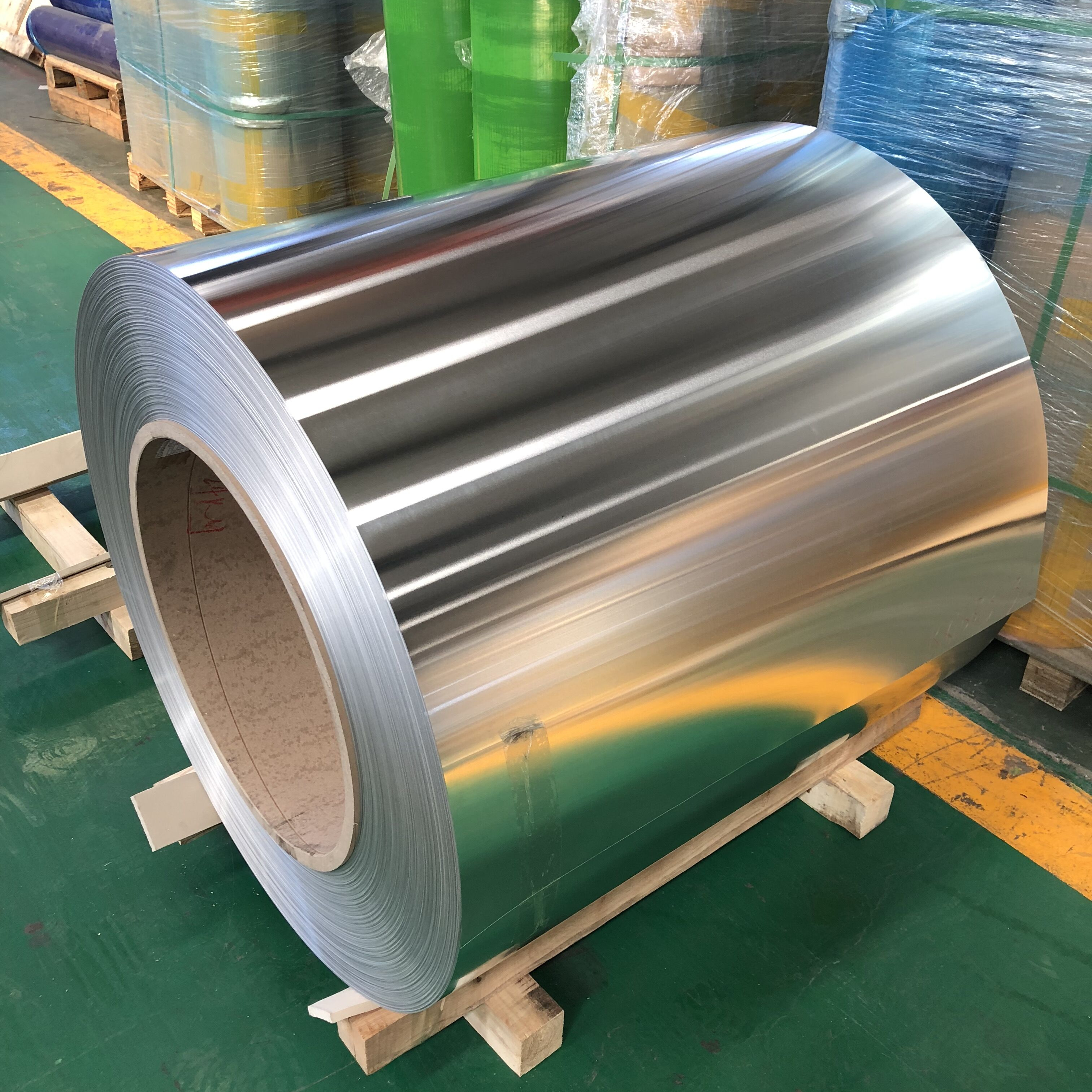

Zeao Custom Anodized Aluminum Coil Aluminum Sheet H12 Supplier

.

aluminum she.

Performance advantages of aluminum plate:

1.It has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity

2.can be gas welding, hydrogen welding and contact welding

3.easy to bear all kinds of pressure processing and extension, bending

Product Description

Tempering:O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34H36,H38,H111,H112,H114,H 116,H321

Surface:mill,bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc

Thickness: 0.15-500mm;

Width: 20-1300mm;

Length: 500-6000mm or above;

Thickness tolerance: + 0.05mm;

Width / length tolerance: + 2mm;

Minimum quantity: 5-10 tons;

Market application

5052 alloy aluminum plate is widely used in the manufacture of fuel tanks, oil pipes and transportation vehicles, ship sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, molds, etc. It can also be used for low load parts that require high plasticity and good weldability, working in liquid or gaseous media, such as fuel tanks, gasoline or lube oil conduits, various liquid containers and other small load parts made with deep drawing: Wire is used to make rivets.

Car Lightweight fuel tank Aluminum bin Aluminum mold

Five Advantages

- Complete product range: Has a complete range of aluminum, aluminum, aluminum tape products

- 15 years of production and sales experience: Customized products can be cut as required, good quality and good price

- Excellent distribution team: The company has 10 delivery vehicles, ready to ship

- Sufficient spot sale: Stock spot nearly 60,000 tons

- Production equipment and production line: The company has a slitter and tablet scale precision

Zeao is a trusted manufacturer of high-quality anodized aluminum coil and sheet H12. Our anodized aluminum products are made using the finest quality aluminum alloys and are designed to meet the high standards of different industries. We offer custom solutions for different applications, including construction, automotive, electronics, and more.

Specifications

Our anodized aluminum coil and sheet H12 comes in different sizes and specifications to meet our customers' needs. Here are some of the specifications of our anodized aluminum products:

- Material: aluminum alloy

- Temper: H12

- Surface Treatment: Anodized

- Thickness: 0.2-5.0mm

- Width: 20-2200mm

- Length: Customizable

Features and Benefits

The high standards of different industries and applications are met by our anodized aluminum products. Here are some of the features and benefits of our anodized aluminum coil and sheet H12:

-

High Strength: Our anodized aluminum products have an excellent strength-to-weight ratio, making them ideal for use in various applications.

-

Corrosion Resistance: Our anodized aluminum products are very resistant to corrosion, so they can be used in harsh conditions.

-

Versatility: Our anodized aluminum products are flexible and can be used to make a wide range of things, such as building materials, auto parts, electronic parts, and more.

-

Customization: We can make sizes, specifications, and surface treatments to meet our customers' needs.

Quality Control

At Zeao, we are committed to providing our customers with high-quality products. To ensure the quality of our anodized aluminum products, we have implemented a strict quality control process that includes the following:

- Material Inspection: All aluminum alloys that come in are checked to make sure they meet our high standards.

- Controlling the anodizing process: We keep an eye on every step of the anodizing process to make sure that our anodized aluminum products meet the standards.

- Final Inspection: We check all finished products one last time to make sure they meet the needs of the customer.

Applications

Our anodized aluminum coil and sheet H12 is used in many industries and for many different tasks. Here are some of the applications of our anodized aluminum products:

- Construction Materials

- Automotive Parts

- Electronics Components

- Solar Panel Frames

- Decorative Materials

Zeao's high-quality anodized aluminum coil and sheet H12 are perfect for many uses in many industries. Our anodized aluminum products are made using the finest quality aluminum alloys and are designed to meet the high standards of different industries. We can make solutions that fit the needs of our customers by letting them choose the size, specifications, and surface treatments. Contact us today to learn more about our anodized aluminum products and how they can benefit your manufacturing process.

| Grade | Chemical Composition(%) | Others | AI | ||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Single | Tol | 99.5 | |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.7 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.03 | 0.03 | - | 99 |

| 1100 | 0.95 | 0.05~0.4 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | Remains | |

| 3003 | 0.6 | 0.7 | 0.05~0.2 | 1.0~1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8 | - | 0.25 | - | 0.05 | 0.15 | Remains |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.2~0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | Remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | Remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | 0.1 | - | 0.05 | 0.15 | Remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4~0.1 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6~3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | Remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | Remains |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2~0.7 | 3.5~4.5 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

| 6063 | 0.2~0.6 | 0.35 | 0.1 | 0.1 | 0.45~0.9 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remains |

| 6041 | 0.4~0.8 | 0.7 | 0.15~0.4 | 0.15 | 0.04~0.35 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

Market ApplicationMarket application

5052 alloy aluminum plate is widely used in the manufacture of fuel tanks, oil pipes and transportation vehicles, ship sheet metal parts, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, molds, etc. It can also be used for low load parts that require high plasticity and good weldability, working in liquid or gaseous media, such as fuel tanks, gasoline or lube oil conduits, various liquid containers and other small load parts made with deep drawing: Wire is used to make rivets.

oil fume purifier

LCD back

Rice cooker liner

The refrigerator panel

Recommend Products

-

Aluminum Coil Zeao Aluminum Sheet H12 Supplier

Magnesium is the main alloying element in the 5052 alloy aluminum plate. It is the most widely used rust-proof aluminum. The alloy has high strength, especially fatigue resistance: high plasticity and corrosion resistanc

-

Aluminum Coil Zeao Aluminum Sheet 5052

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum foil products, complete specifications, huge capacity,

-

Zeao Custom Anodized Aluminum Coil Aluminum Sheet H12 Supplier

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum coil/sheet/foil products etc, complete specifications,

-

O-H112 Temper and 5052 Grade plain aluminium coil Manufacturer | aluminum plate

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum foil products, complete specifications, huge cap

-

5052 Aluminum Strip Used For Tank/Side Light Channelume Aluminum Strip for LED Sign Letter &Signboard

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum foil products, complete specifications, huge cap