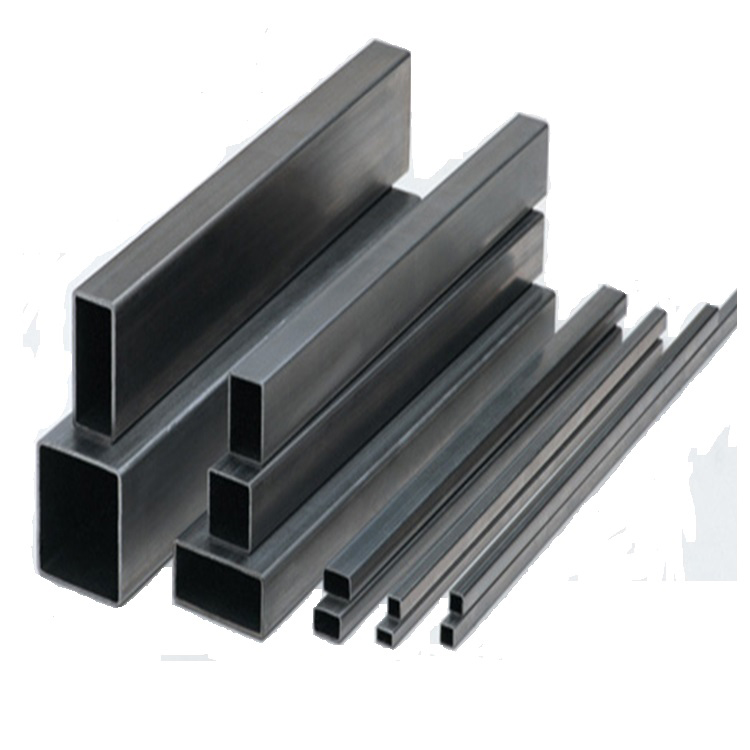

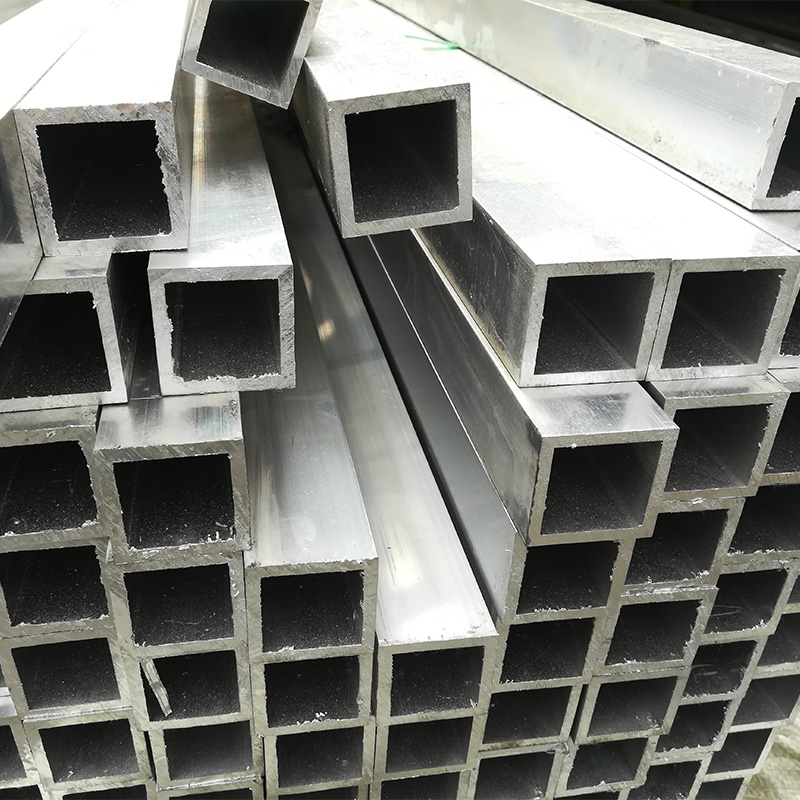

Good Quality Aluminum Tube 6061/Square tube / Aluminum Pipe for Auto Parts Aluminum Extrusion Anodized extruded aluminum t slot

Ze'ao 6063 T5 Aluminum Round Pipe Square Tubing are a high quality, anodized aluminum extrusion. Can be used in furniture components, architecture, automotive accessories and so on

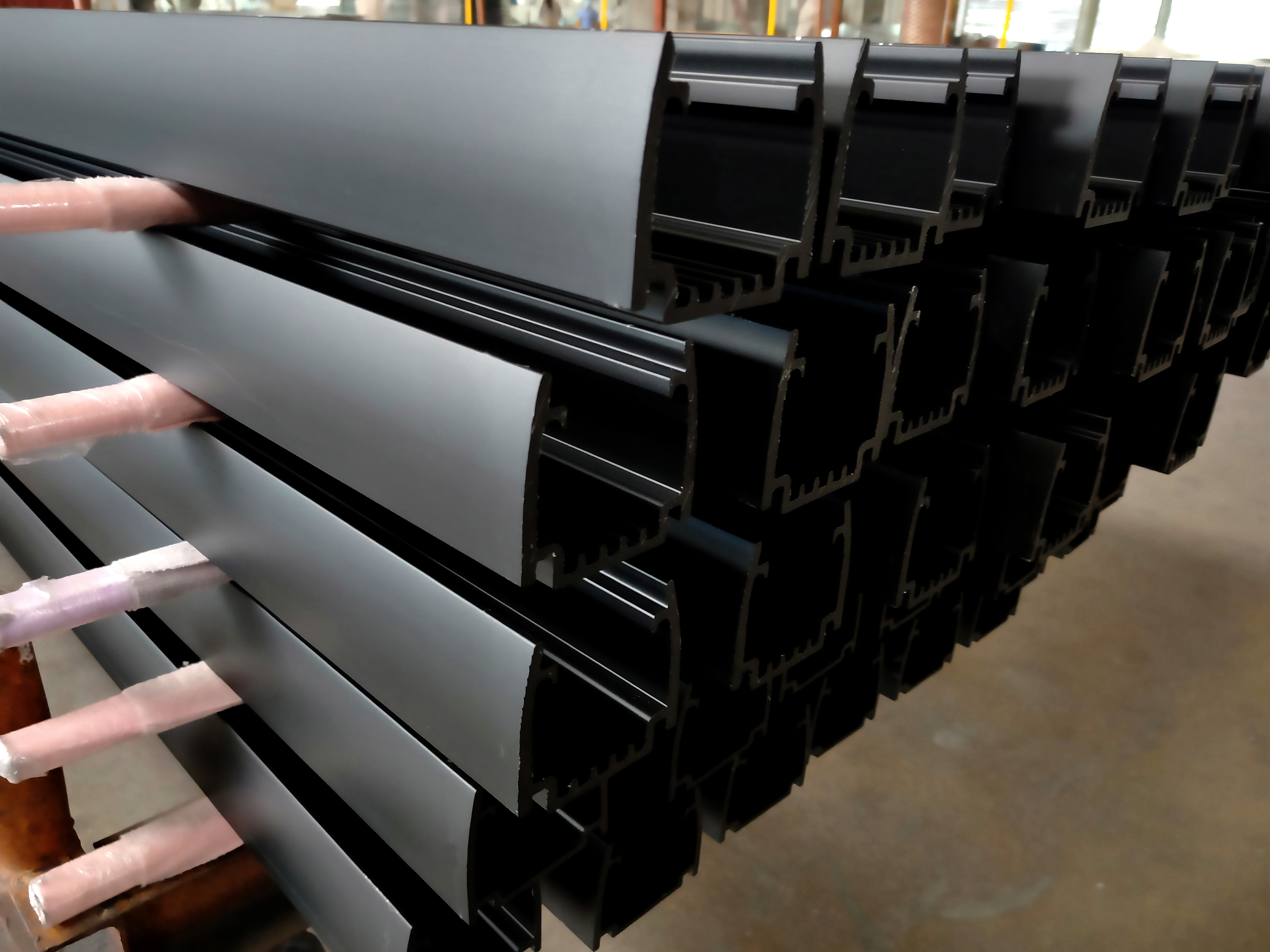

Aluminum Extrusion with T Slots | Extruded Aluminum T Slot

Certificate Aluminum Profile System Competitive Advantage

-

Engineering design and support.

-

Aluminium profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

-

High Quality system, strictly inspection during production and whole inspection before package.

-

Good performance, product warranty for 15 years.

extruded aluminum t slot

2. Strict quality control and inspection before goods delivery.

3. Production standards: GB5237-2008, QUOLANOD, JIS or other International standards.

4. With 23 years experience, our factory is well recognised by clients and enjoys a good reputation among overseas markets.

5.While being awarded various honors, our brand Yalian Aluminium Profiles is rated as Guangdong Famous Brand by the government and our factory is rated as the enterprise which can always honor our contracts and keep commercial integrity.

6. Strong R&D team and over 100 national patents.

Zeao is one of the biggest companies that makes high-quality aluminum tubes for many different industries, including the auto industry. Our aluminum tubes are made using the finest quality aluminum alloys, including 6061. Our aluminum tubes are designed to meet the high standards of the automotive industry, making them the perfect choice for various applications in auto parts.

Specifications

Our aluminum tubes come in a wide range of sizes and specifications to meet our customers' needs. Here are some of the specifications of our aluminum tubes:

- Material: 6061 aluminum alloy

- Surface Treatment: anodized, polished, powder coated

- Shape: Round, Square, or Rectangular

- Wall Thickness: 0.5mm to 50mm

- Length: Customized

Features and Benefits

Our aluminum tubes for auto parts are designed to meet the high standards of the automotive industry. Here are some of the features and benefits of our aluminum tubes:

-

High Strength: Our aluminum tubes have an excellent strength-to-weight ratio, making them ideal for use in various applications in auto parts.

-

Corrosion Resistance: Our aluminum tubes are very resistant to corrosion, so they can be used in harsh conditions.

-

Good thermal conductivity: Aluminum is a great heat conductor, so our aluminum tubes are perfect for uses that need good thermal conductivity.

-

Versatility: Our aluminum tubes are flexible and can be used to make a wide range of auto parts, such as parts for the engine, suspension, transmission, and more.

-

Customization: We can make sizes, specifications, and surface treatments to meet our customers' needs.

Quality Control

At Zeao, we are committed to providing our customers with high-quality products. To ensure the quality of our aluminum tubes, we have implemented a strict quality control process that includes the following:

- Material Inspection: All aluminum alloys that come in are checked to make sure they meet our high standards.

- Controlling Production: We keep an eye on every step of the production process to make sure that our aluminum tubes meet the requirements.

- Final Inspection: We check all finished products one last time to make sure they meet the needs of the customer.

Applications

Our aluminum tubes for auto parts are widely used in the automotive industry. Here are some of the applications for our aluminum tubes:

- Engine Components

- Suspension Components

- Transmission Components

- Steering Components

- Brake Components

- Exhaust Systems

- Heat Exchangers

Zeao's high-quality aluminum tubes for auto parts are the best choice for many uses in the auto industry. Our aluminum tubes are made using the finest quality aluminum alloys and are designed to meet the high standards of different industries. We can make solutions that fit the needs of our customers by letting them choose the size, specifications, and surface treatments. Contact us today to learn more about our aluminum tubes and how they can benefit your manufacturing process.

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.70 | 0.50 |

| Cu | 0.10 | 0.10 | 0.15~0.40 | 0.10 |

| Mn | 0.10 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.10 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.10 | 0.15 | 0.25 | 0.20 |

| Ti | 0.10 | 0.10 | 0.15 | 0.10 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.50 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

| Item | ALUMINUM PROFILE | ||||||

| Material | 6000 series Aluminium | ||||||

| Temper | T4 | T5 | T6 | ||||

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. | ||||||

| Shape | Square | Round | Rectangular | Customized | |||

| Application | In furniture, windows&doors, decorations ,industry, construction and so on | ||||||

| Surface treatment | powder coating | electrophoresis | wood grain | anodized | Brushed | Polishing | |

| Colors | Ref powder coating color sheet and customized color available | ||||||

| Deep process | DCNC | Drilling | Milling | Cutting | Welding | bending | assembling |

| Certificate | CQM, SGS, CE, BV, SONCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available | ||||||

| Material & Temper | Aluminum Alloy 6063-T5,6061-T6 |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1000 tons per month. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| OEM | Available. |

Recommend Products

-

Extruded Aluminum T Slot Alloy 6063-T5, 6061-T6 Aluminum Extrusion T Slot Aluminium Profile

Service We provide: 1. Professional technical team Suggestions improvement for you about your aluminium t channel drawings. 2. Professional quality inspectors to ensure the quality and compliance of your aluminium t sl

-

Good Quality Aluminum Tube 6061/Square tube / Aluminum Pipe for Auto Parts Aluminum Extrusion Anodized extruded aluminum t slot

Product Description Ze'ao 6063 T5 Aluminum Round Pipe Square Tubing are a high quality, anodized aluminum extrusion. Can be used in furniture components, architecture, automotive accessories and so on