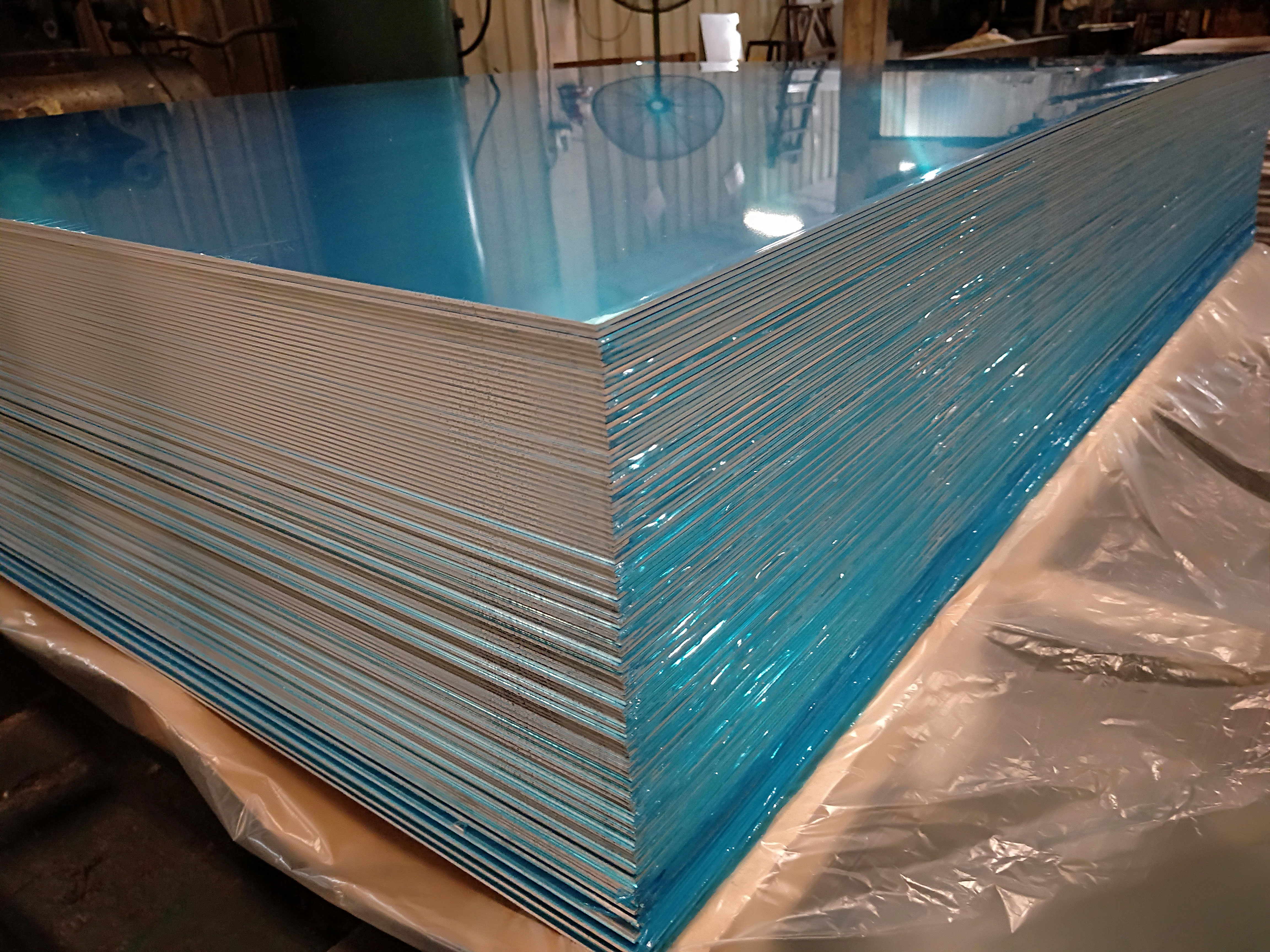

China Supplier Aluminium Sheet 1000 Series 1070/1100/10601050 O H14 H24 H112 For Multiple Uses | aluminum sheet

Product introductionaluminum she

Mechanical properties:Tensile strength (σb): 170~305MPa

Conditional yield strength σ0.2 (MPa)≥65

Modulus of elasticity (E): 69.3~70.7Gpa

The annealing temperature was 345 °C.

Product Description

Tempering:O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34H36,H38,H111,H112,H114,H 116,H321

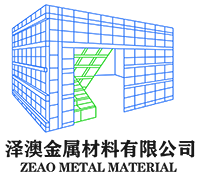

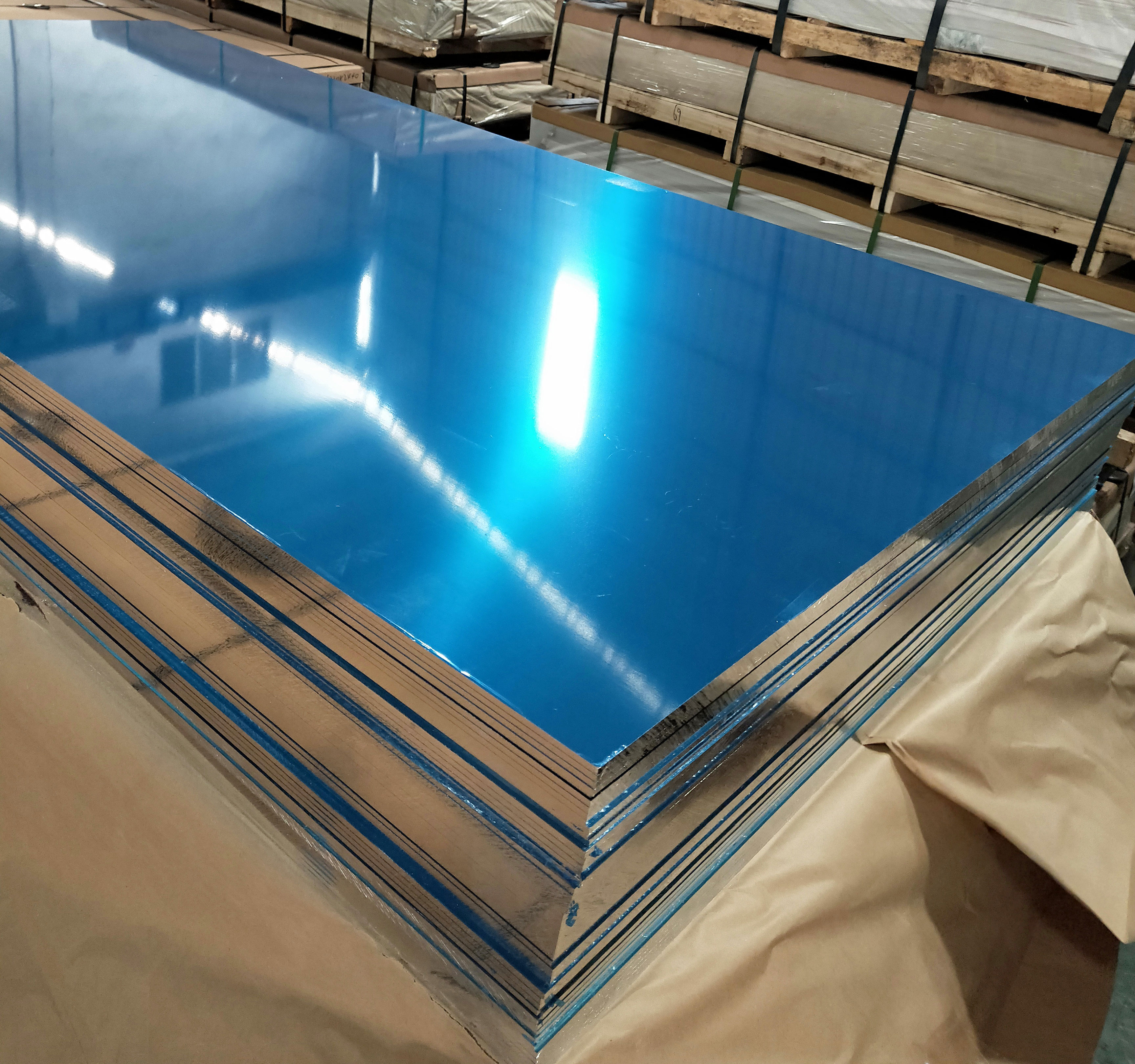

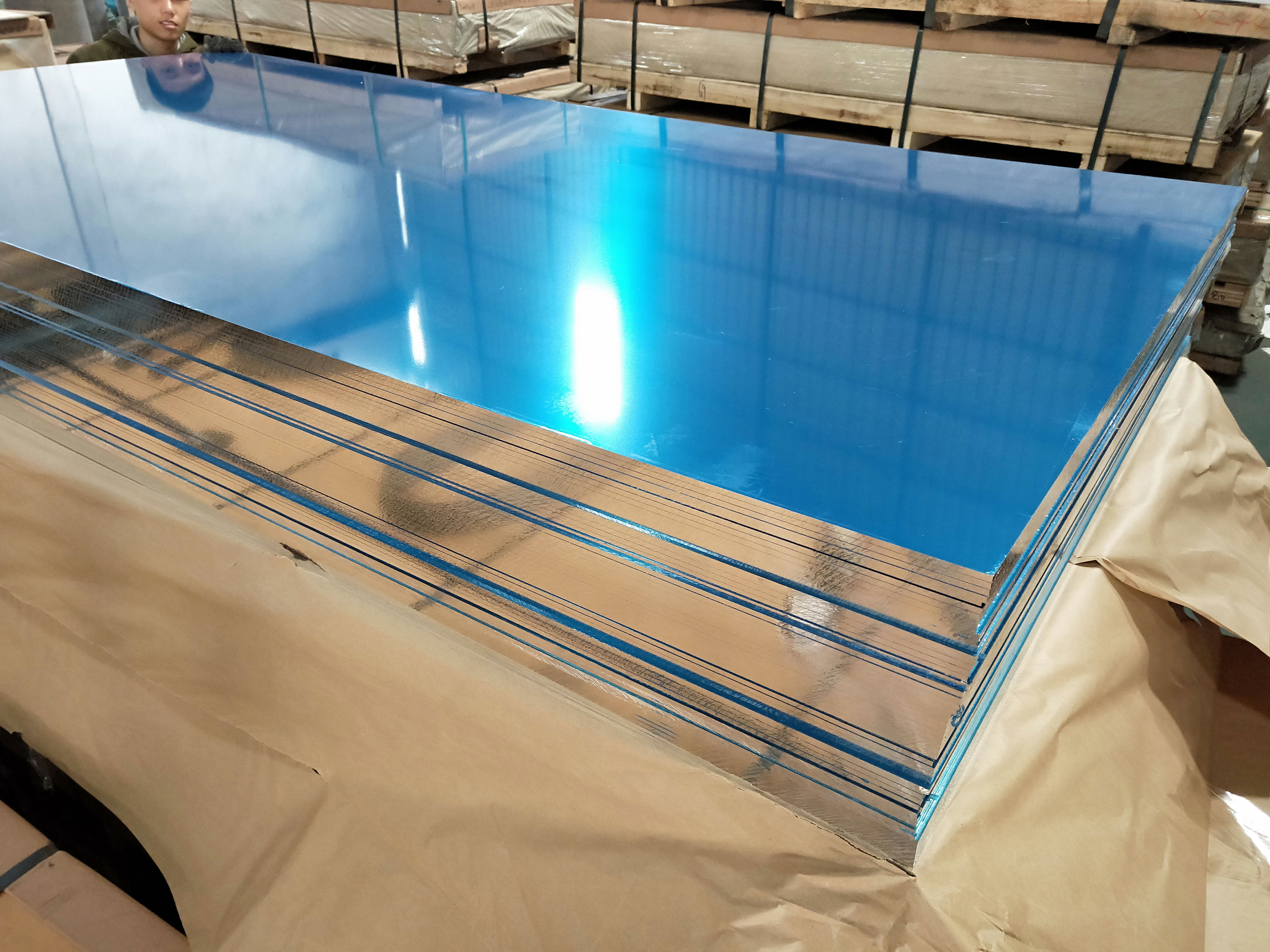

Surface:mill,bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc

Thickness: 0.15-500mm;

Width: 20-1300mm;

Length: 500-6000mm or above;

Thickness tolerance: + 0.05mm;

Width / length tolerance: + 2mm;

Minimum quantity: 5-10 tons;

Market application

1 series aluminum plate typical use: power battery casing, automobile heat shield, fuel tank, water tank, automobile skid plate, battery explosion-proof valve, battery cover, automobile interior, signage, cans, medical equipment, etc.;

Car Lightweight fuel tank Aluminum bin Aluminum mold

Five Advantages

- Complete product range: Has a complete range of aluminum, aluminum, aluminum tape products

- 15 years of production and sales experience: Customized products can be cut as required, good quality and good price

- Excellent distribution team: The company has 10 delivery vehicles, ready to ship

- Sufficient spot sale: Stock spot nearly 60,000 tons

- Production equipment and production line: The company has a slitter and tablet scale precision

| Grade | Chemical Composition(%) | Others | AI | ||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Single | Tol | 99.5 | |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.7 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.03 | 0.03 | - | 99 |

| 1100 | 0.95 | 0.05~0.4 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | Remains | |

| 3003 | 0.6 | 0.7 | 0.05~0.2 | 1.0~1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8 | - | 0.25 | - | 0.05 | 0.15 | Remains |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.2~0.6 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | Remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | 0.1 | 0.05 | 0.15 | Remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | 0.1 | - | 0.05 | 0.15 | Remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4~0.1 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6~3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | Remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | Remains |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2~0.7 | 3.5~4.5 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

| 6063 | 0.2~0.6 | 0.35 | 0.1 | 0.1 | 0.45~0.9 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remains |

| 6041 | 0.4~0.8 | 0.7 | 0.15~0.4 | 0.15 | 0.04~0.35 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remains |

More advantages are used to manufacture some structural parts with specific properties, such as gaskets and capacitors made of aluminum foil, outer casings of electronic products, isolation pipes for electronic tubes, protective sleeves for wires and cables, nets, cores and aircraft ventilation system parts and decorative parts.

Aircraft parts

Electric appliance

Electronic product enclosure

Lithium polymer battery

Recommend Products

-

China Supplier Aluminium Sheet 1000 Series 1070/1100/10601050 O H14 H24 H112 For Multiple Uses | aluminum sheet

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum foil products, complete specifications, huge capacity,

-

High Quality 1060/1050/1070/1100 H14/H24/h16/H26 Aluminum Alloy coil/strip | aluminum sheet metal

Ze 'ao is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing.The company can produce 1-8 series aluminum foil products, complete specifications, huge cap

-

1000 Series O/H12/H22/H14/H24 Temper Mirror FInish Aluminum Coil

The 1000 Series aluminum plate contains more than 99.5% aluminum and is one of industrial pure aluminum. The 1000 series aluminum plate has high plasticity, corrosion resistance, electrical conductivity and thermal condu