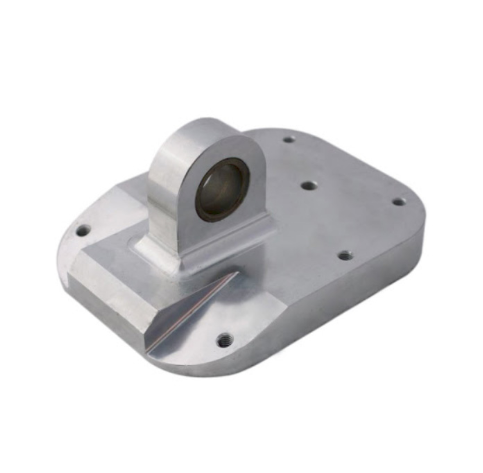

Custom OEM CNC Aluminum Turning Parts Machining Import Direct Auto Parts | CNC Aluminum Parts

Custom CNC Alulminum Manufacturers | Custom CNC Parts Manufacturers - Zeao

CNC Machining Aluminum Parts

6061-T6 aluminum properties include its structural strength and toughness. It is also offers good finishing characteristics and responds well to anodizing, including clear, clear and color dye, and hardcoat. 6061 aluminum alloy is also easily welded and joined. However, in its –T6 condition the welds may lose some strength, which can be restored by re-heat-treating and artificially aging.

Aluminum in its purest form is too soft and reactive to be of structural use. However, its alloys, such as 6061-T6 alloy, make it structurally stronger and more useful in the manufacturing of durable products.

6061-T6 aluminum properties make it a material of choice for builders of boats and watercraft because it’s strong and lightweight. It is ideal for sailboat masts and for hulls of larger yachts that cannot be made from fiberglass. Small, flat-bottom canoes are almost entirely fabricated from 6061-T6, although the bare aluminum is often coated with protective epoxy to improve its resistance to corrosion.

Other common applications of 6061-T6 aluminum include bicycle frames, applications where heat transfer is required, such as heat exchangers, air coolers and heat-sinks, and applications where 6061-T6’s non-corrosive characteristics are important, such as water, air and hydraulic piping and tubing.

Aluminum 6061-T6 alloy conducts and dissipates heat well. Since it can be extruded, it can be formed into almost any imaginable shape.

Application:

cnc aluminum parts

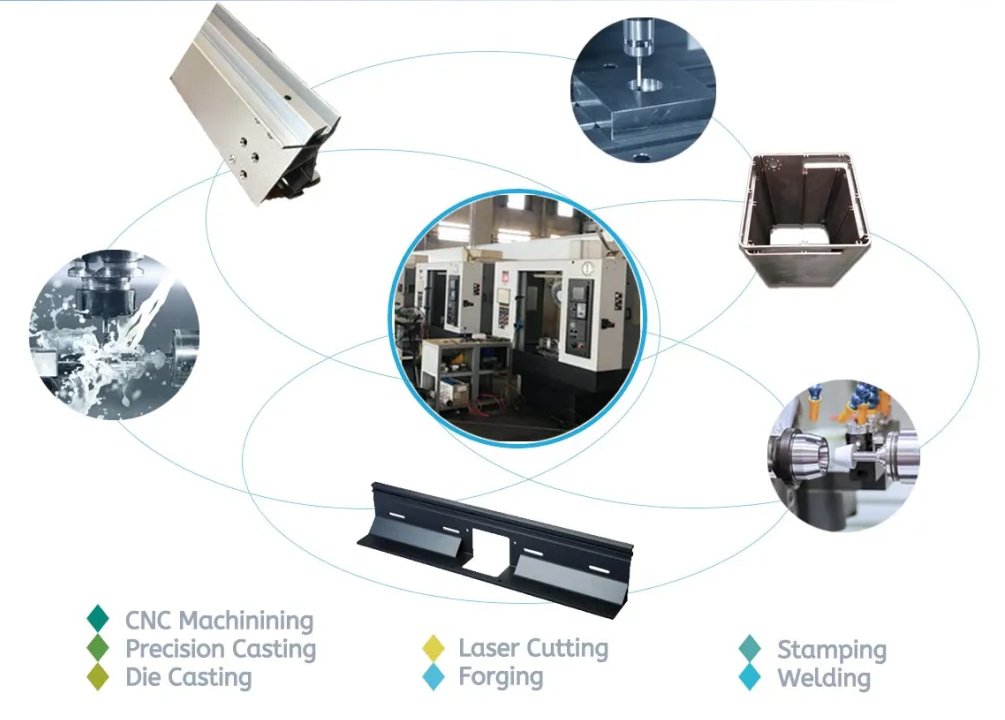

- cnc machining 2.precision 3.die casting 4.laser cutting 5.forging 6.stamping 7.welding

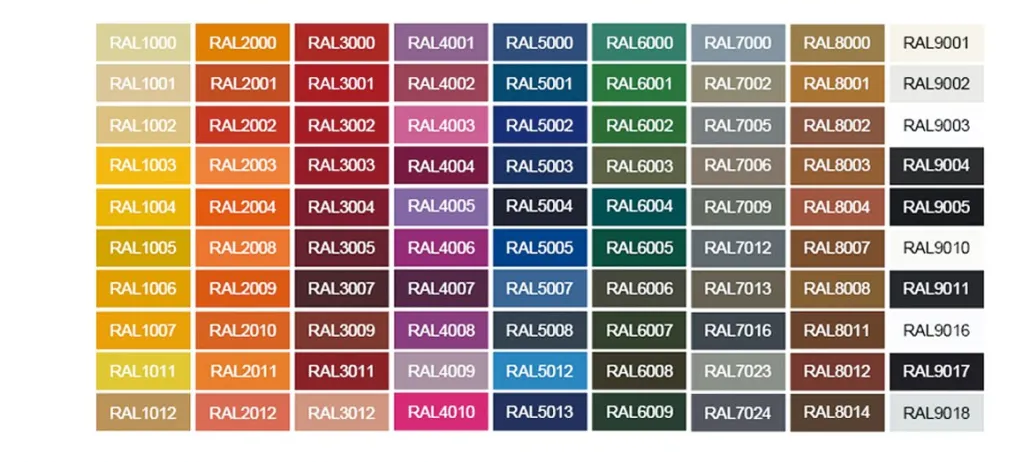

Color sample

Zeao is a leading manufacturer of high-quality, custom OEM CNC aluminum turning parts for auto parts. Our CNC aluminum parts are made using the latest machining technology and the finest quality aluminum alloys. We offer a wide range of CNC aluminum turning parts that are custom made to meet the specific requirements of our customers.

Specifications

Our CNC aluminum turning parts come in a range of sizes and specifications to meet our customers' needs. Here are some of the specifications of our CNC aluminum turning parts:

- Material: aluminum alloy, stainless steel, brass, copper, plastic, etc.

- Tolerance: +/- 0.005mm

- Finish: anodizing, sandblasting, electroplating, painting, powder coating, etc.

- Surface Roughness: Ra0.4

- Machining processes include turning, milling, drilling, grinding, wire EDM, etc.

Features and Benefits

Our custom OEM CNC aluminum turning parts for auto parts are designed to meet the high standards of the automotive industry. Here are some of the features and benefits of our CNC aluminum turning parts:

-

High Precision: Our CNC aluminum turning parts are made with the most up-to-date technology, so they are very accurate and precise.

-

Durability: Our CNC aluminum turning parts are made using the finest quality aluminum alloys, which makes them highly durable and long-lasting.

-

Corrosion Resistance: Aluminum is very resistant to corrosion, which makes our CNC aluminum turning parts perfect for use in harsh environments.

-

Customization: We offer sizes, specs, and finishes that are made to order to meet the needs of each customer.

Quality Control

At Zeao, we are committed to providing our customers with high-quality products. To ensure the quality of our custom OEM CNC aluminum turning parts for auto parts, we have implemented a strict quality control process that includes the following:

- Material Inspection: All materials that come in are checked to make sure they meet our high standards.

- Production Control: We watch every step of the production process to make sure that our CNC aluminum turning parts meet the requirements.

- Final Inspection: We check all finished products one last time to make sure they meet the needs of the customer.

Applications

Our custom OEM CNC aluminum turning parts for auto parts are widely used in the automotive industry. Here are some of the applications for our CNC aluminum turning parts:

- Engine Components

- Suspension Components

- Transmission Components

- Steering Components

- Brake Components

- Electrical Components

- Body Components

Zeao's custom OEM CNC aluminum turning parts for auto parts are the perfect choice for the automotive industry. Our CNC aluminum turning parts are made using the finest quality aluminum alloys and the latest machining technology. With custom sizes, specifications, and finishes available, we can provide custom solutions to suit the specific needs of our customers. Contact us today to learn more about our CNC aluminum turning parts and how they can benefit your automotive manufacturing process.

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.70 | 0.50 |

| Cu | 0.10 | 0.10 | 0.15~0.40 | 0.10 |

| Mn | 0.10 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.10 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.10 | 0.15 | 0.25 | 0.20 |

| Ti | 0.10 | 0.10 | 0.15 | 0.10 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.50 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

| Item | ALUMINUM PROFILE | ||||||

| Material | 6000 series Aluminium | ||||||

| Temper | T4 | T5 | T6 | ||||

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. | ||||||

| Shape | Square | Round | Rectangular | Customized | |||

| Application | In furniture, windows&doors, decorations ,industry, construction and so on | ||||||

| Surface treatment | powder coating | electrophoresis | wood grain | anodized | Brushed | Polishing | |

| Colors | Ref powder coating color sheet and customized color available | ||||||

| Deep process | DCNC | Drilling | Milling | Cutting | Welding | bending | assembling |

| Certificate | CQM, SGS, CE, BV, SONCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available | ||||||

| Material & Temper | Aluminum Alloy 6063-T5,6061-T6 |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1000 tons per month. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| OEM | Available. |

Recommend Products

-

Custom OEM CNC Aluminum Turning Parts Machining Import Direct Auto Parts | CNC Aluminum Parts

We are specialized custom CNC alulminum manufacturers from China, CNC machining aluminium parts, CNC aluminum machining suppliers/factories, wholesale high-quality products of Aluminum CNC Parts R & D and manufacturi

-

Precision Custom Factory Wholesale Aluminum CNC Parts Milling Part | custom cnc aluminum

Zeao is a manufacturer of cnc machining parts with factory who has a strong products develop team with many experienced workers; We don't offer any ready made cnc machining parts and are manufacturing the

-

Precision CNC Machining Aluminum CNC Parts/CNC aluminum alloy processing | Machined Aluminum Parts Manufacturers

Ze'ao is a manufacturer of cnc machining parts with factory who has a strong products develop team with many experienced workers; We don't offer any ready made cnc machining parts and are manufacturing

-

Alloy 6000 Series CNC Custom Aluminum CNC Parts | machined aluminum extrusion

Ze'ao Industrial is a leading manufacturer of CNC machined Parts in China. We provide CNC Machined Parts , CNC milling & turning parts , CNC Precision Turned Part and Aluminum CNC Machined Pa

-

Aluminum Radiator Core/Aluminum Radiator/Aluminum Heatsink | aluminum machined parts

Ze'ao Industrial is a leading manufacturer of CNC machined Parts in China. We provide CNC Machined Parts , CNC milling & turning parts , CNC Precision Turned Part and Aluminum CNC Machined Pa