What Is CNC And What Can It Bring?

What is CNC machining and why is it important?

Now, from small-scale industries to large companies, CNC has become a part of us without knowing it. Everyone involved in manufacturing should know what CNC machine tools can bring to their company.

There is hardly any aspect of manufacturing that is not affected by automated CNC machining. Therefore, CNC machine tools have been widely used in various industries.

● What is CNC machining?

WorKing video | CNC machined Parts

The term CNC is short for "computer numerical control". Computer numerical control refers to the use of computer systems to manipulate traditional machines, a method for performing various manufacturing tasks, which are all performed by computerized equipment.

With the increasing application of computers in industrial manufacturing processes, CNC machining services have become common.

Traditional industrial equipment such as center lathes, routers, drilling rigs, and milling machines are operated by computers to achieve better control. The computer numerical control process is fast and repeatable, making it ideal for manufacturing parts with tight tolerances.

● Why is CNC machining important?

The cost and quality of manufactured parts depends on the accuracy and efficiency of their production. Today, many industries use CNC machining to aid in production because it simplifies the manufacturing process.

The advantages of CNC are applicable to almost any industry. Because CNC machines can machine virtually any type of material, their applications are virtually limitless.

To ensure accuracy, high tolerances, quality, and long-term durability, manufacturers need to use CNC machining to create high-quality molds. Manufacturers use CNC to create this high precision, replacing manually operated machines, vertical mills, and lathes with centralized automated systems that allow for more accurate and efficient production.

What advantages does CNC machining have?

We cannot ignore the importance of CNC, do you know the advantages and development trends of CNC machining.

● Higher-production efficiency

One of the most important reasons for using CNC machining for production is production efficiency. Compared to manual production, since computers are used to control the machines, this means that all major production operations can be automated to increase the speed and quality of manufacturing.

In the absence of special circumstances, CNC machines can perform long production runs, an efficiency that could never be achieved through a manual process.

● Improve product accuracy

CNC machines are programmable and every detail of the production process can be fed into the machine. There is no doubt that CNC processes are more accurate than manual machining, they can be repeated in the same way over and over again, providing the ability to produce complex shapes with high precision, even very complex designs can be produced, reducing human error.

● Flexible craftsmanship

CNC machines increase automation and reduce the number of operators needed to operate the machine. At the same time, the CNC operating process offers flexibility in that while the CNC offers relatively complex functions and operations, the fundamentals of the process remain essentially the same through all of them.

● Safety

The CNC process is able to reduce manpower, simplify work steps, and perform the required operation of the machine without human intervention, largely avoiding the occurrence of accidents.

● Time-saving

CNC requires highly skilled professionals, and skilled operators can already run multiple tools simultaneously. Machining execution takes very little time, and the precise and repetitive process minimizes time consumption and unnecessary waste.

What products can CNC machines bring you?

CNC machine processes are suitable for a wide range of materials, including metals, plastics, glass, and composites. As a result, CNC machining facilitates a variety of applications across different industries.

● Vehicle parts

The automotive industry often uses CNC milling machines for the design and production of different parts for different types of vehicles, such as gearboxes, valves, shafts, and various other components.

● Electronic field

In the consumer electronics industry, the CNC machining process helps manufacture housings, fixtures, fixtures, and other electronic components.

● Architecture

Materials such as metal pipes, tubes, wood, and other metals for architectural projects can come from CNC. Also, CNC is best suited for the architectural design process to create detailed structural models made of plastic and composite materials.

● Healthcare sector

The high performance of medical components is critical, and CNC machining can include surgical instruments, electronic housings, orthopedic devices, implants, and a variety of other medical safety materials.

What types of CNC Aluminum Patrs there are?

As we all know, aluminum CNC parts and aluminum CNC service are play an important role in our life and different industry.

You can custom CNC aluminum as you need. From plastics to metals to fiberglass, CNC machining can be done with materials that are rigid enough, however, aluminum is the most popular material of the bunch.

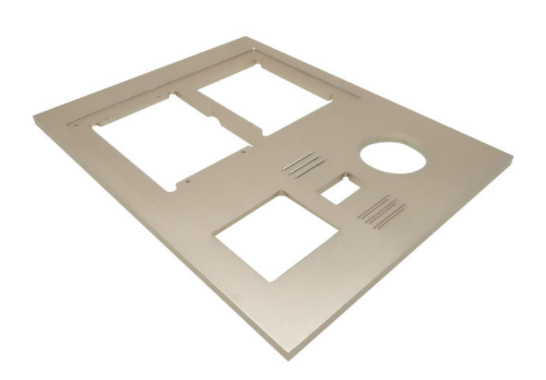

● CNC aluminum panel processing

Aluminum sheets are easy to process, and when alloying elements are added, deformed aluminum alloys with good casting properties or good processing plasticity can be obtained.

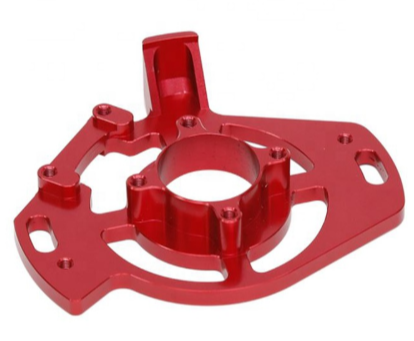

● CNC aluminum profile processing

CNC aluminum profile machining with stable quality, high processing accuracy, and repeatability, suitable for various processing requirements.

● CNC aluminum alloy processing

Aluminum alloy extruded products have good surface quality and high precision, which improves the utilization rate of metal materials and the yield rate.

● CNC aluminum shell processing

CNC machining aluminum with high precision, whether it is a conventional aluminum profile shape or a complex profile cross-section, can be perfectly CNC machined.

Conclusion

Advances in manufacturing cannot be made without advances in CNC technology. No matter what industry you're in, you're sure to find some type or another of CNC machine and CNC parts.

ZEAO has the leading melt casting production lines, intelligent extrusion equipment, and deep processing centers that are able to provide you with different aluminum products including CNC aluminum machining parts.

If you are interested in aluminum profiles, please take the initiative to contact us for an initial consultation for more information.