The Benefits of 3003 Aluminum Sheet for Your Next Project

As a top company that makes things, Zeao knows how important it is to choose the right materials for your project. If you're looking for a versatile and cost-effective material for your next project, 3003 aluminum sheet may be the answer.We'll explore the benefits, applications, and pros and cons of 3003 aluminum sheet to help you determine if it's the right choice for your project.

Choosing the right material for your project is essential to ensuring its success. 3003 aluminum sheet is a versatile and cost-effective material that offers several advantages. In this article, we'll explore the benefits, applications, and pros and cons of 3003 aluminum sheet to help you determine if it's the right choice for your next project.

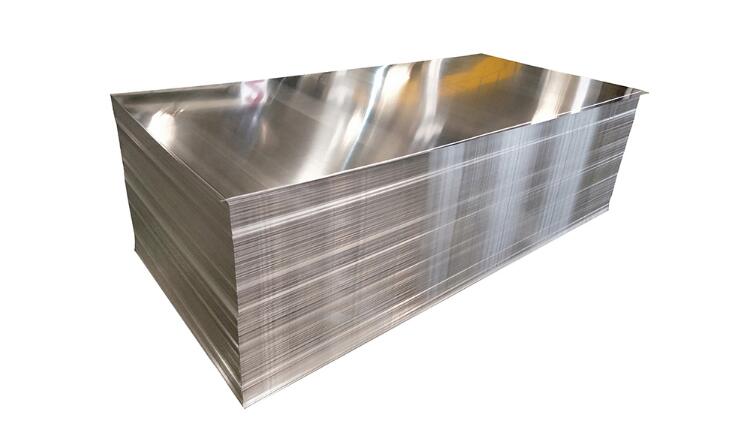

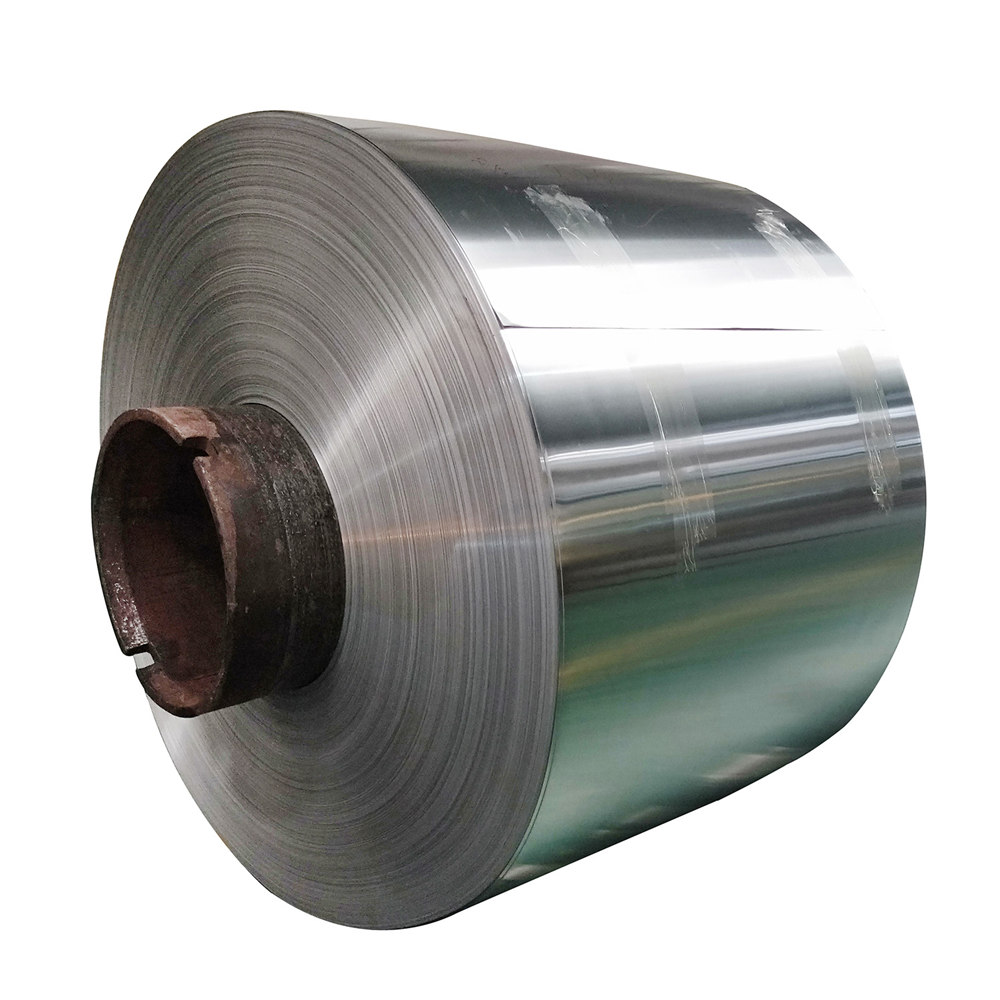

What is 3003 aluminum sheeting?

3003 aluminum sheet is an alloy that is made up of aluminum, manganese, and a small amount of copper. This combination results in a material that is highly versatile and has excellent formability. Also, 3003 aluminum sheet doesn't rust easily, so it's often used in situations where moisture is a problem.

Applications of 3003 Aluminum Sheet

3003 aluminum sheet is a versatile and widely used material that finds applications in various industries. It is an aluminum-manganese alloy that provides good corrosion resistance, excellent workability, and moderate strength. This makes it a suitable choice for applications that require a combination of strength, formability, and corrosion resistance. In this section, we will discuss some of the most common applications of 3003 aluminum sheet.

Roofing and siding

3003 aluminum sheet is often used for roofing and siding in the building industry. Its excellent corrosion resistance and durability make it an ideal material for these applications. The aluminum sheet is lightweight and easy to install, which reduces labor costs and time. Moreover, it can withstand harsh weather conditions, such as extreme temperatures, UV rays, and moisture.

Food and Chemical Handling Equipment

The food and chemical industries require materials that are safe and resistant to corrosion. 3003 aluminum sheet is an excellent choice for food and chemical handling equipment because it is non-toxic, non-magnetic, and resists corrosion. It is also easy to clean and sanitize, which is crucial in these industries.

Trailer Siding and Roofing

Most of the time, 3003 aluminum sheet is used to make the sides and roofs of trailers. Its good strength-to-weight ratio and resistance to corrosion make it a good choice for these uses. Also, it's easy to shape the aluminum sheet into different shapes, which is important for trailers with unique designs.

Heat Exchangers

Heat exchangers are important parts in many industries, such as the automotive, aerospace, and heating, ventilation, and air conditioning (HVAC) industries. Heat exchangers should be made of 3003 aluminum sheet because it is both good at transferring heat and resistant to corrosion. Its low density also makes it a good material for making heat exchangers lighter, which makes them work better.

Lighting Reflectors

3003 aluminum sheet is widely used in the lighting industry for reflector purposes. Its high reflectivity and good formability make it an excellent material for producing lighting reflectors. The aluminum sheet can be easily shaped into different shapes and provides a bright and reflective surface that enhances the efficiency of lighting systems.

Cooking Utensils

Cooking tools like pots, pans, and baking sheets are often made out of 3003 aluminum sheet. It is a great choice for these uses because it is good at transferring heat and doesn't rust. The aluminum sheet is also non-toxic and does not react with acidic or alkaline foods, which makes it safe for cooking.

3003 aluminum sheet is a versatile and widely used material that finds applications in various industries. Its excellent corrosion resistance, workability, and moderate strength make it a suitable choice for applications that require a combination of these properties. Whether you are in the construction, food, chemical, or lighting industries, 3003 aluminum sheet has something to offer.

Pros of 3003 Aluminum Sheet

There are several advantages to using 3003 aluminum sheet for your next project, including:

- Versatility: 3003 aluminum sheet can be easily formed into various shapes, making it ideal for a wide range of applications.

- Corrosion resistance: 3003 aluminum sheet has excellent resistance to corrosion, making it an ideal material for outdoor applications or those that are exposed to moisture.

- Cost-effective: 3003 aluminum sheet is relatively inexpensive compared to other aluminum alloys, making it a cost-effective option for projects that require high-quality materials without breaking the budget.

Cons of 3003 Aluminum Sheet

Even though 3003 aluminum sheet has some good points, it also has some bad points, such as:

- Lower strength: 3003 aluminum sheet is not as strong as other aluminum alloys, making it less suitable for applications that require high strength.

- Limited temperature range: 3003 aluminum sheet has a lower melting point than some other aluminum alloys, limiting its use in high-temperature applications.

Frequently Asked Questions

Q: What is the difference between 3003 and 5052 aluminum sheet?

A: 3003 aluminum sheet has a higher manganese content than 5052 aluminum sheet, making it more formable but less strong.

Q: Can 3003 aluminum sheet be welded?

A: Yes, 3003 aluminum sheet can be welded using standard welding techniques.

Q: Is 3003 aluminum sheet suitable for outdoor applications?

A: Yes, 3003 aluminum sheet is very resistant to corrosion, which makes it perfect for use outdoors or in wet environments.

Conclusion

3003 aluminum sheet is a great choice for projects that need a material that can be used in many ways and doesn't cost much. It doesn't rust and is easy to shape, which makes it great for a wide range of uses, such as roofing and siding, equipment for handling food and chemicals, and lighting reflectors. Even though it might not be good for projects that need a lot of strength or a lot of heat, it is a popular choice for many projects because of its benefits. Zeao has high-quality 3003 aluminum sheet for sale and can help you choose the right material for your project.

In conclusion, the 3003 aluminum sheet is a great choice for a wide range of uses because it is easy to work with, doesn't rust, and is inexpensive. It may not be good for uses that need high strength or high temperatures, but it is a great material for roofing and siding, as well as equipment for handling food and chemicals and light reflectors. As one of the aluminum circle sheet manufacturers and aluminum circle sheet suppliers in China, Zeao offers high-quality 3003 aluminum sheets and can help you determine if it's the right material for your next project.