How to Choose the Right Aluminum Extrusion for Your Project

Aluminum extrusions are used in a wide range of projects because they are strong, durable, and easy to work with. However, choosing the right aluminum extrusion for your project can be a daunting task. With so many options available on the market, it can be challenging to know where to start. In this article, we will explore how to choose the right aluminum extrusion for your project.

We know how important it is to choose the right aluminum extrusion for your project at Zeao. Our wide variety of aluminum extrusions is made to meet the needs of many different industries and uses. Whether you're looking for a lightweight and durable extrusion for a transportation project or a strong and robust extrusion for a building or construction project, we have the expertise and experience to help you find the perfect solution.

When it comes to selecting the right aluminum extrusion, there are several factors to consider. These include how the extrusions can be used, the pros and cons of each, and answers to questions that are often asked. Let's take a closer look at each of these factors.

Application

When choosing the right aluminum extrusion for your project, the first thing you need to consider is its application. What is the purpose of your project, and what are the specific requirements that your extrusion needs to meet?

For example, if you're designing a structure that requires a high level of durability and strength, you may want to choose a heavy-duty extrusion with a thicker wall. These extrusions are ideal for applications where there is a lot of weight or stress, such as heavy machinery or structural supports. On the other hand, if you're designing a lightweight structure, a thinner extrusion with a smaller wall thickness may be more suitable. When weight is an issue, like in the aerospace or automotive industries, these extrusions are perfect.

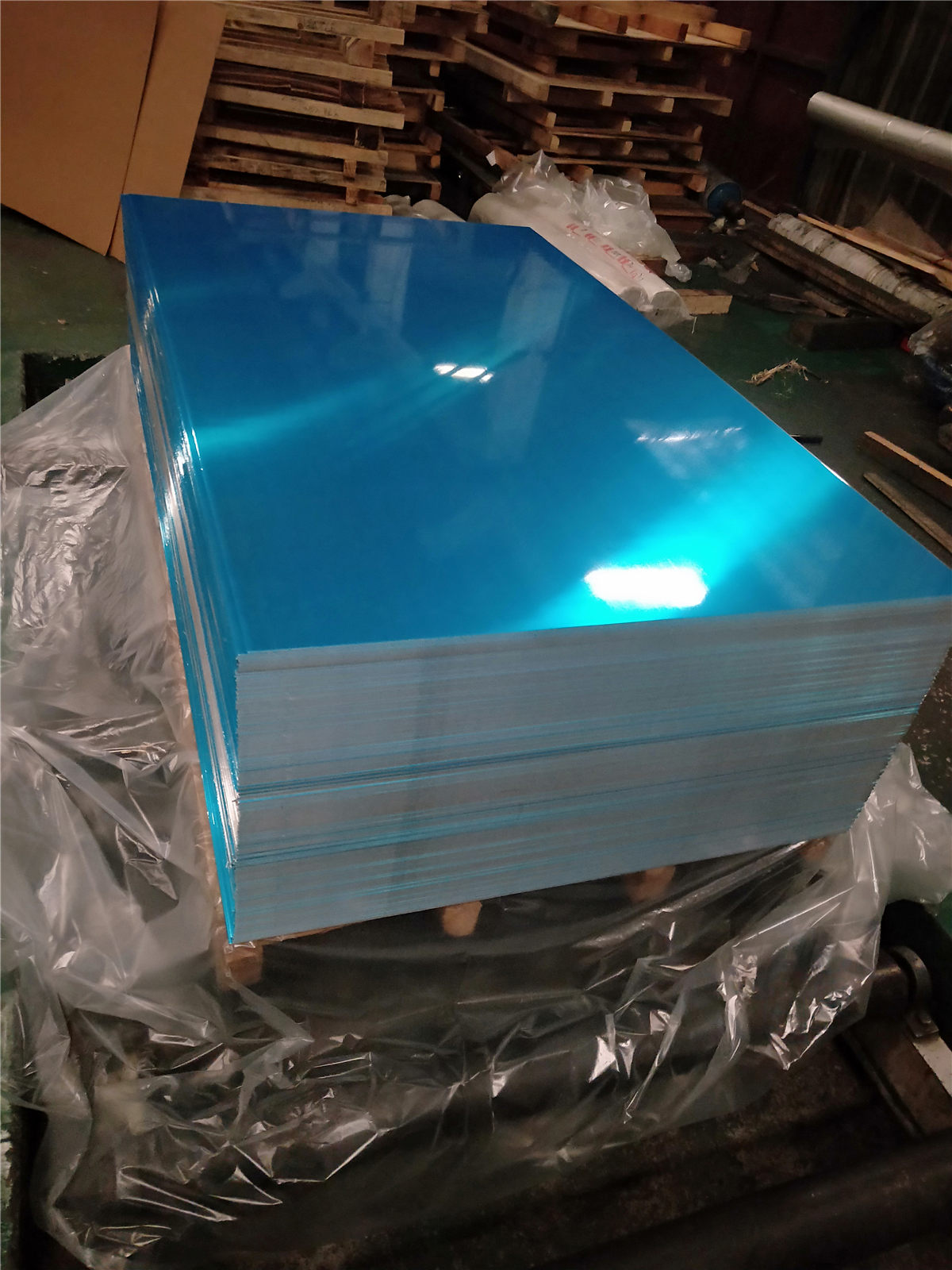

It's also important to consider the environment in which your extrusion will be used. If your project will be exposed to harsh weather conditions, extreme temperatures, or corrosive chemicals, you'll need to choose an extrusion that is resistant to these conditions. Anodized aluminum extrusions, for example, are highly resistant to corrosion and can withstand exposure to a wide range of environmental factors.

By carefully thinking about how your project will be used and what your extrusion needs to do, you can choose the right aluminum extrusion for your needs. Whether you're building a heavy-duty structure or a lightweight prototype, there is an aluminum extrusion that is perfectly suited to your project's needs.

Pros and Cons

Once you know what your project needs, it's important to think about the pros and cons of the different aluminum extrusions. There are several types of aluminum extrusions available on the market, each with their own strengths and weaknesses. For example, T-slot aluminum extrusions are a popular choice for building frames, workstations, and other structures. They are versatile and easy to assemble, but may not be as strong as other types of extrusions.

Another type of extrusion is the V-slot aluminum extrusion, which is commonly used for linear motion applications. V-slot extrusions are popular for robotics and automation projects because they are strong, last a long time, and offer a lot of support. However, they can be more challenging to assemble than T-slot extrusions.

At Zeao, we understand that choosing the right aluminum extrusion for your project can be challenging. That's why we offer a range of services, including technical support and custom extrusion design, to help you find the perfect solution for your needs. Contact us today to learn more about our range of aluminum extrusions and how we can help you choose the right extrusion for your project.