FAQs of Aluminum Parts Manufacturing

Aluminum is a lightweight, silvery metal that can be made into almost any shape. It can be rolled into thick sheets or used as a thin foil for wrapping paper, or it can be drawn into wire and made into cans.

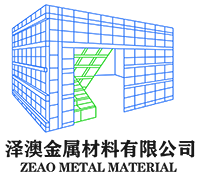

Pure aluminum is soft and has limited strength; small amounts of elements, such as copper, magnesium, and zinc, are often added to increase strength. Machined aluminum parts manufacturers can manufacture complex aluminum parts by CNC machining. With the widespread use of light metals, machined aluminum parts are becoming the choice in many industries.

CNC machined aluminum parts for applications requiring lightweight design, electrical conductivity, high strength, and good corrosion resistance.

What is aluminum CNC machining?

Aluminum CNC machining is the process of cutting and removing excess materials from an aluminum workpiece until the final object with desired geometries. CNC machining aluminum can create complex aluminum parts with high accuracy.

Why choose CNC aluminum and related products?

Aluminum is easy to work with and is an exceptional material for parts production. Overall, aluminum parts can be machined three times faster than the same parts made of steel, and have better corrosion resistance than steel. You will also save on tooling, and for aluminum machining, production costs are reduced.

If the hardness of aluminum meets your requirements, we recommend that you consider this alloy for part fabrication. In this case, you will save money on materials, which will help reduce manufacturing time.

What are the materials available for CNC machining?

Available materials for CNC aluminum machining are Al6061, Al6063, AL7075, AL5052, etc.

Do not rush to make a decision when choosing aluminum alloy for your project. The right alloy may significantly improve the technical characteristics of your product.

How do the CNC aluminum machining manufacturers perform CNC machining?

The CNC machining process generates a part on a CNC machine from a computer design file.

The process will go through:

● Load the CAD (Computer Aided Design) file into CAM (Computer Aided Manufacturing) software.

● Determine tool paths based on the part geometry.

● CAM software creates digital instructions or G-Code that tells the machine what to do and how to do it.

● CNC machines take to execute the operations as the programming language.

Are aluminum alloy CNC parts durable?

Aluminum and aluminum alloy are ideal materials for making mechanical parts, and surface treatments such as anodizing will help aluminum parts have a harder outer layer that is resistant to corrosion and impact.

What surface finishes are available for CNC aluminum machining?

CNC machining aluminum manufacturers are often able to offer a variety of surface finishing options, including machining, polishing, sandblasting, anodizing, and more.

Where can CNC machined aluminum parts be used?

CNC aluminum parts can be found everywhere, in a range of industries, especially industrial equipment and machinery, automotive, aerospace, and consumer and computer electronics.

How much does CNC machining aluminum parts cost?

Prices are based on the structure of the part, order volume, machining processes, etc. You can get in touch with Zeao for more information.

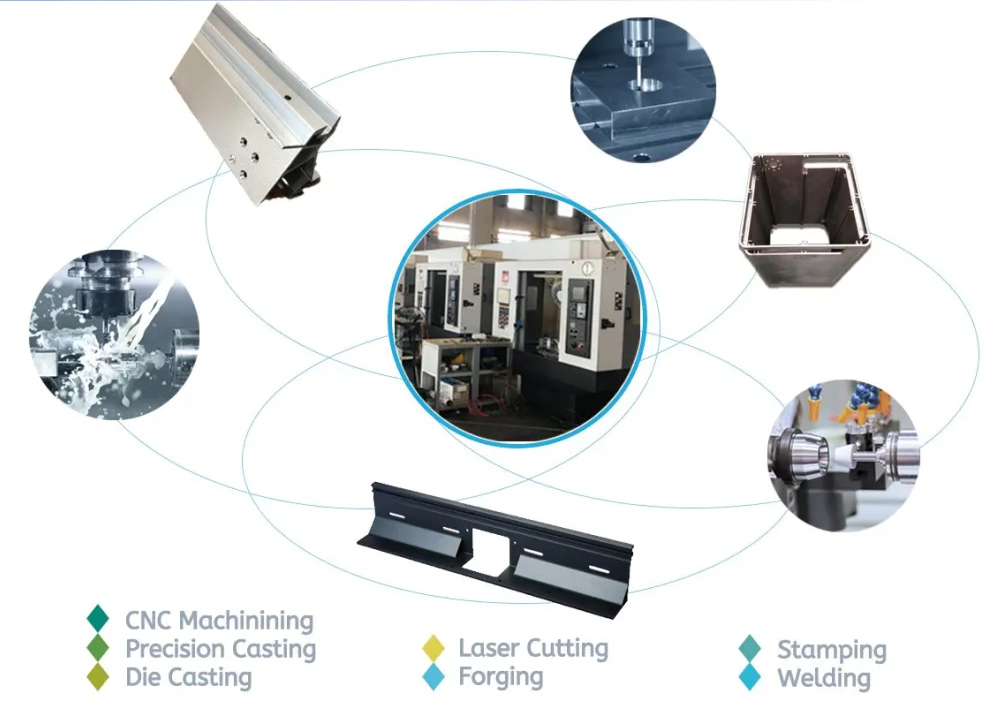

Custom CNC parts manufacturers

Zeao is a manufacturer of CNC machining parts with a factory that has strong product development and a team with many experienced workers. We manufacture custom CNC machined parts according to your drawings or existing samples.

We provide CNC machined parts, CNC milling & turning parts, CNC precision turned parts and aluminum CNC machined parts of high quality and competitive price.

We offer unrivaled expertise in precision aluminum part machining and finishing. Zeao constantly improves techniques and upgrades technology to provide the best product to our customers.