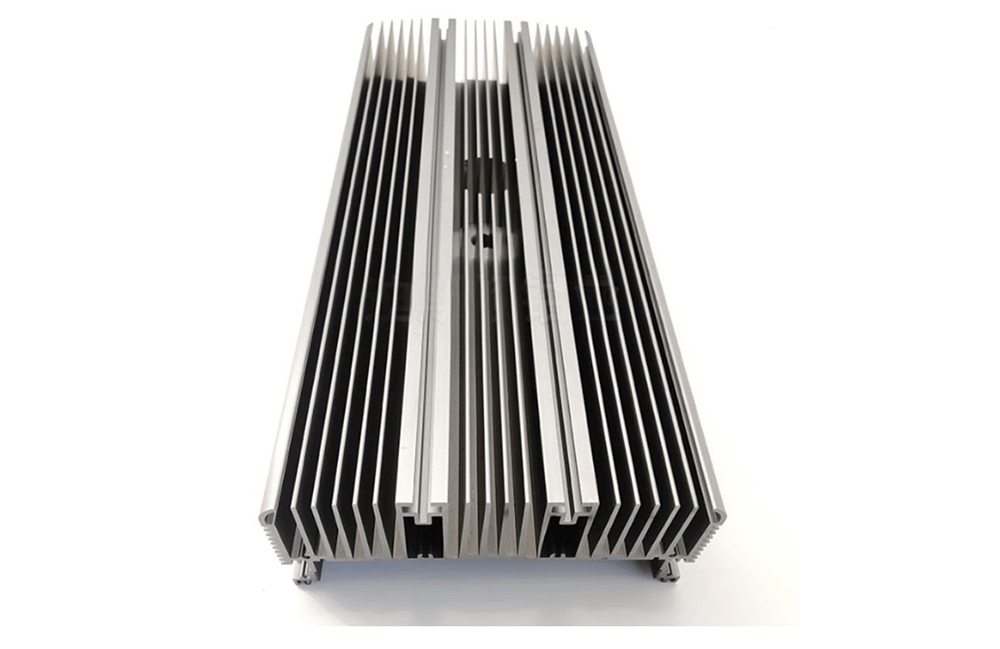

Extrusion of aluminum alloy profile | architectural aluminum extrusion profiles

/product/precision-machined-aluminum-cnc-machined-parts-manufacturer-cnc-aluminum-profile-processing.html

The extrusion of aluminum alloy profiles is carried out on an automatic production line composed of ingot heating, extrusion, cooling, tension straightening, and sawing. The equipment on the production line includes induction heating furnace, extruder, discharge table, discharge conveyor, profile lifting and conveying device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc. The heating temperature of the ingot is generally controlled at 400 ℃ ~ 520 ℃, the temperature is too high or too low will directly affect the extrusion molding. The extruder generally uses a single-acting hydraulic press with a tonnage between 1200 tons and 2500 tons. The diameter of the extrusion cylinder of the extruder varies with the tonnage of the extruder. The tonnage of the extruder is large, and the diameter of the extrusion cylinder is also large. The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360℃~460℃, and the extrusion speed is 20m/min~80m/min. Extrusion tools mainly include dies. Extrusion molds are divided into flat molds, split molds, tongue molds and split combined molds according to their structural characteristics. Flat molds and split combined molds are used for the production of aluminum alloy door and window profiles. The discharging station receives the profile extruded from the extruder and transfers the profile to the discharging work station. The discharging workbench is mostly a horizontal conveyor type, and its horizontal movement speed is synchronized with the extrusion speed. The cooling bed is mostly walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profile, so that the temperature of the profile before straightening is lower than 70 ℃. The tension leveler is equipped with twisting jaws, which can be stretched and straightened while twisting and correcting. Behind the tension leveler is the storage table, which provides profiles to the sawing machine worktable, and the sawing machine cuts the profiles according to a fixed length.

architectural aluminum extrusion profiles

The extrusion of aluminum alloy profiles is carried out on an automatic production line composed of ingot heating, extrusion, cooling, tension straightening, and sawing. The equipment on the production line includes induction heating furnace, extruder, discharge table, discharge conveyor, profile lifting and conveying device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc. The heating temperature of the ingot is generally controlled at 400 ℃ ~ 520 ℃, the temperature is too high or too low will directly affect the extrusion molding. The extruder generally uses a single-acting hydraulic press with a tonnage between 1200 tons and 2500 tons. The diameter of the extrusion cylinder of the extruder varies with the tonnage of the extruder. The tonnage of the extruder is large, and the diameter of the extrusion cylinder is also large. The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360℃~460℃, and the extrusion speed is 20m/min~80m/min. Extrusion tools mainly include dies. Extrusion molds are divided into flat molds, split molds, tongue molds and split combined molds according to their structural characteristics. Flat molds and split combined molds are used for the production of aluminum alloy door and window profiles. The discharging station receives the profile extruded from the extruder and transfers the profile to the discharging work station. The discharging workbench is mostly a horizontal conveyor type, and its horizontal movement speed is synchronized with the extrusion speed. The cooling bed is mostly walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profile, so that the temperature of the profile before straightening is lower than 70 ℃. The tension leveler is equipped with twisting jaws, which can be stretched and straightened while twisting and correcting. Behind the tension leveler is the storage table, which provides profiles to the sawing machine worktable, and the sawing machine cuts the profiles according to a fixed length.

architectural aluminum extrusion profiles