Creating Customized Aluminum Extrusion Shapes

Creating Customized Aluminum Extrusion Shapes for Your Project Aluminum extrusions are versatile and customizable materials used in a wide range of industries. From aerospace to construction, these materials are used to create custom shapes and sizes to meet specific project requirements. At Zeao, we understand the importance of creating unique aluminum extrusion shapes that meet our customers' needs.

In this article, we'll talk about how to make custom aluminum extrusion shapes, as well as their uses, pros, cons, and frequently asked questions.

How to Make Custom Aluminum Extrusion Shapes

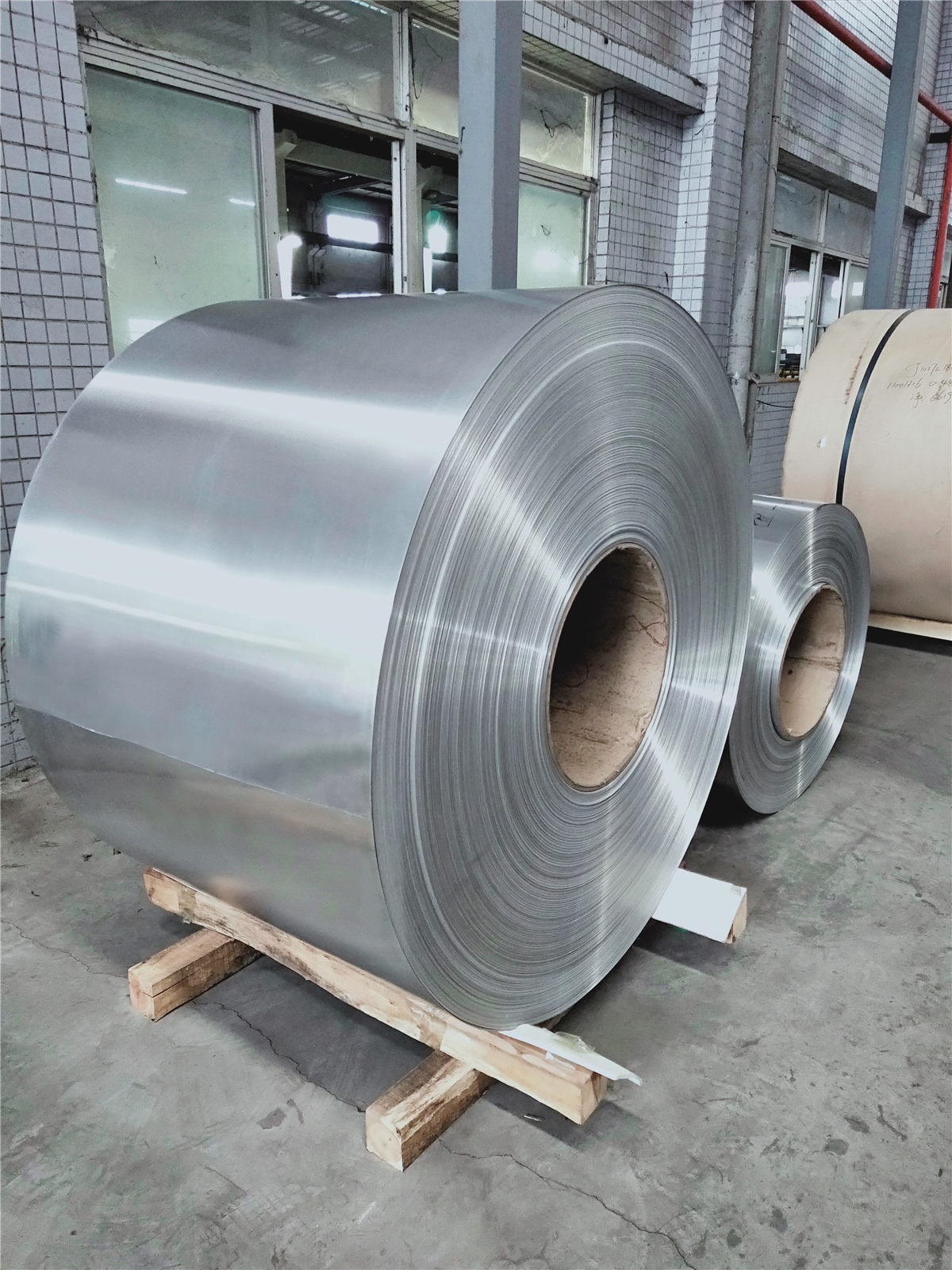

Aluminum extrusion is the process of forcing an aluminum alloy through a die to make a custom shape. The shapes made from extruded aluminum can be used for many things, such as in the aerospace, automotive, construction, and electronics industries. Here are the steps involved in making custom aluminum extrusion shapes:

Step 1: Design

The first step in making custom aluminum extrusion shapes is to create a design. The design should include the shape, size, and other specifications of the part. The design can be created using CAD software or by hand. The design should take into account the properties of aluminum, such as its strength, weight, and corrosion resistance.

Step 2: Die Creation

Once the design is complete, the next step is to create a die. The die is a tool that is used to shape the aluminum into the desired shape. The die is made from tool steel and is created using a CNC machine. The die must be able to withstand the pressure of the aluminum as it is forced through it.

Step 3: Extrusion

After the die is created, the extrusion process can begin. The aluminum alloy is heated to a specific temperature and then forced through the die using a hydraulic press. The pressure of the press forces the aluminum through the die, creating the desired shape.

Step 4: Cooling and cutting

After the aluminum is extruded through the die, it is cooled using a water bath or air cooling. Once the aluminum has cooled, it is cut to the desired length using a saw. The extruded aluminum shapes can then be further processed or used as is.

Making custom aluminum extrusion shapes involves designing the part, creating a die, extruding the aluminum, and cutting it to size. The process requires specialized equipment and expertise, making it a job best left to professionals. To learn more about aluminum extrusion and its applications, visit the Zeao Aluminum website.

Applications of Customized Aluminum Extrusion Shapes

Aluminum extrusion shapes can be used to make a wide range of products with different shapes and sizes. They are a versatile and cost-effective way to do this. Customized aluminum extrusion shapes give manufacturers even more freedom, letting them make parts that meet the needs of a wide range of industries. Here are some of the applications of customized aluminum extrusion shapes:

Aerospace Industry

The aerospace industry demands high-strength materials that are lightweight and durable. Customized aluminum extrusion shapes provide these qualities and are widely used in aircraft structures, engine components, and other parts. The extruded aluminum shapes used in aerospace must meet stringent safety and quality standards, making customized shapes an ideal choice.

Automotive Industry

In the automotive industry, custom aluminum extrusion shapes are becoming more and more popular because they can make parts that are both light and strong. Structural components, heat exchangers, and body panels are just some of the parts made from extruded aluminum shapes. Additionally, aluminum is corrosion-resistant, making it a great choice for automotive applications.

Construction Industry

Customized aluminum extrusion shapes can be used for many things in the construction industry, such as framing systems, curtain walls, window and door frames, and other architectural uses. Aluminum shapes that have been extruded can be made in many different ways, which makes them a popular choice for modern buildings.

Electronics Industry

The electronics industry relies on extruded aluminum shapes to make heat sinks and other parts that help move heat away from electronic devices. Aluminum is a great way to get rid of heat from sensitive electronic parts because it is a great heat conductor.

In the end, customized aluminum extrusion shapes can be used in many different industries for many different things. They are a cost-effective way to make parts that are both light and strong and meet certain requirements. To learn more about aluminum extrusion and its applications, visit the Zeao Aluminum website.

Pros and Cons of Customized Aluminum Extrusion Shapes

Pros:

Versatile: Customized aluminum extrusion shapes can be designed to meet specific project requirements.

Lightweight: extruded aluminum shapes are lightweight and easy to handle, making them an ideal choice for applications where weight is a concern.

High strength: extruded aluminum shapes have a high strength-to-weight ratio, making them ideal for applications where strength is essential.

Corrosion-resistant: Aluminum extrusion shapes are naturally corrosion-resistant, making them ideal for outdoor applications.

Cons:

Cost: Customized aluminum extrusion shapes can be expensive, especially when compared to off-the-shelf standard shapes.

Limited availability: customized shapes may not be readily available, which can lead to longer lead times and delays in project timelines.

Popular FAQs About Customized Aluminum Extrusion Shapes

Q: What is the lead time for custom aluminum extrusion shapes?

A: The lead time for custom aluminum extrusion shapes depends on how complicated the shape is and how many are needed. Typically, lead times range from four to six weeks.

Q: What is the minimum order quantity for custom aluminum extrusion shapes?

A: The minimum order quantity for custom aluminum extrusion shapes varies depending on the shape and its complexity.

Q: Can I get a sample of a custom aluminum extrusion shape before placing an order?

A: Yes, we can make a sample of a custom aluminum extrusion shape for you to look over and approve before we go ahead with the order.

Maximizing Efficiency with Customized Aluminum Extrusion Shapes

At Zeao, we are experts at making custom aluminum extrusion shapes that meet the needs of each customer. We can make sure our customers' projects are done on time and on budget if we work closely with them. Get in touch with us today to find out more about our custom aluminum extrusion shapes and how they can help you make your next project as efficient as possible.