Aluminum Extrusions: A Sustainable Solution for Building Materials

As long as sustainability is a top priority in the building industry, builders are looking for new ways to lessen their impact on the environment. One solution that is gaining popularity is the use of aluminum extrusions as a sustainable building material. At Zeao, we want to help people build things in a way that is good for the environment. In this article, we'll look at why aluminum extrusions are a great choice.

Applications

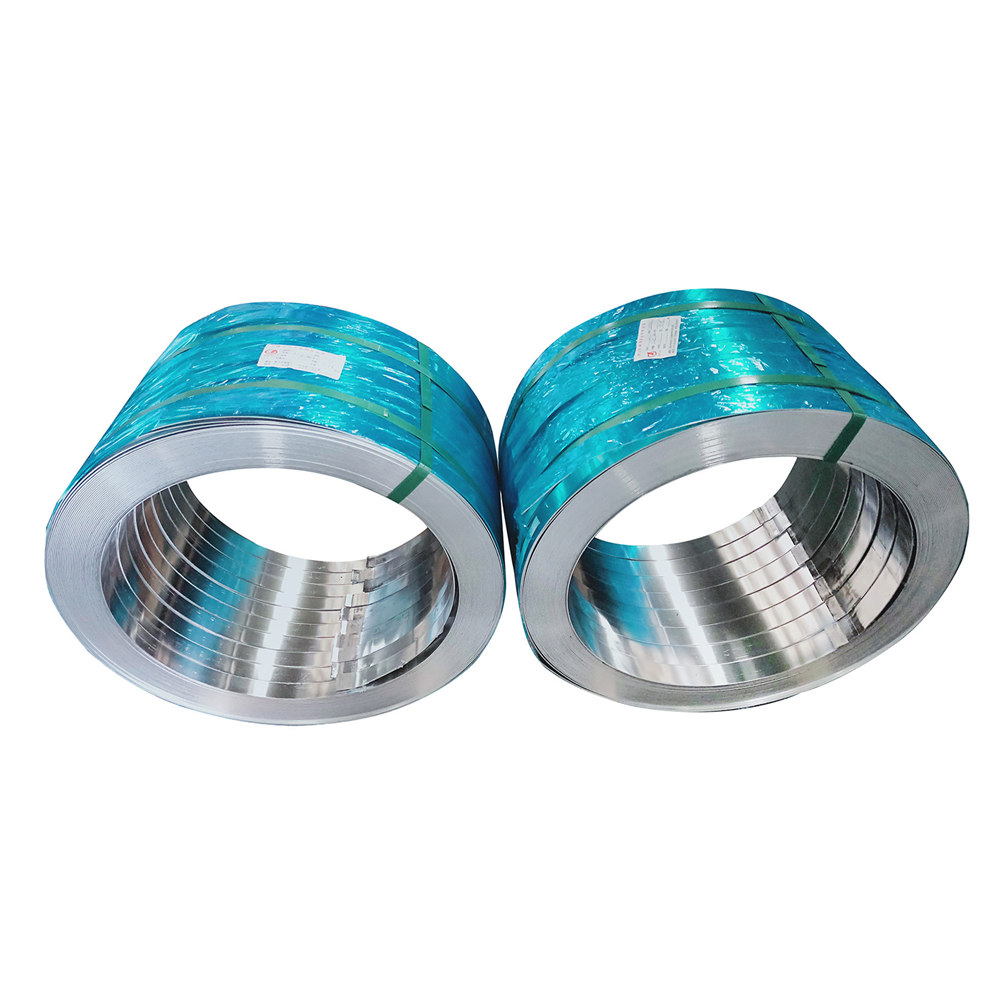

Aluminum extrusions are widely used in the construction industry for various applications. They are versatile, durable, and offer excellent thermal performance, making them a popular choice for architects and engineers. In this section, we will discuss the specific applications of aluminum extrusions in the construction industry, including curtain walls, roofs, and windows.

Curtain Walls

Curtain walls are exterior building systems that are designed to cover the facade of a building. They consist of lightweight aluminum frames that support glass panels or other materials. Aluminum extrusions are an ideal choice for curtain walls because they are strong, lightweight, and corrosion-resistant. They can be customized to fit any building shape or size, and they provide excellent thermal performance, helping to reduce energy costs.

Roofs

Aluminum extrusions are also commonly used in roofing systems. They are lightweight and strong, making them an ideal choice for both flat and pitched roofs. Aluminum extrusions can be customized to fit any size or shape, and they are available in a variety of finishes and colors. They are also resistant to corrosion and weathering, ensuring that they will last for many years.

Windows

Aluminum extrusions are often used to make window frames because they are strong, durable, and resistant to rust. They can be made to fit any size or shape, and they are very good at keeping heat in, which helps cut down on energy costs. Aluminum extrusions also come in many different colors and finishes, which makes them a popular choice among architects and designers.

Aluminum extrusions have a wide range of applications in the construction industry. They are versatile, durable, and offer excellent thermal performance, making them an ideal choice for curtain walls, roofs, and windows. Architects and engineers can customize aluminum extrusions to fit any building shape or size, and they are available in a variety of finishes and colors, ensuring that they will meet the aesthetic needs of any project.

Pros and Cons

One of the best things about aluminum extrusions as a green building material is that they can be recycled. Aluminum is one of the most recyclable materials and can be recycled indefinitely without losing its properties. Other benefits of aluminum extrusions include:

- Durability: Aluminum extrusions are resistant to corrosion and weathering, which makes them a long-lasting solution for construction projects.

- Lightweight: Aluminum extrusions are much lighter than traditional building materials like steel and concrete, which can save money on shipping and installation.

- Energy efficiency: Aluminum extrusions can be designed to offer excellent thermal performance, which can help reduce energy costs and improve the sustainability of buildings.

However, there are some potential drawbacks to aluminum extrusions as a sustainable building material. One concern is the energy required to produce aluminum, which can be significant. Also, aluminum extrusions may be more expensive than some other building materials, but they can be more cost-effective in the long run because they last longer and don't need to be replaced as often.

Frequently Asked Questions

If you're considering using aluminum extrusions as a sustainable building material, you may have some questions. Here are some of the most frequently asked questions about aluminum extrusions:

Can aluminum extrusions be used in green building projects?

Yes, aluminum extrusions can be used in green building projects because of their recyclability, energy efficiency, and durability.

How are aluminum extrusions manufactured?

Aluminum extrusions are made by heating up a block of aluminum and pushing it through a die to make a certain shape.

Are aluminum extrusions safe for indoor air quality?

Yes, aluminum extrusions are safe for indoor air quality because they do not emit volatile organic compounds (VOCs) or other harmful substances.

At Zeao, we are committed to providing sustainable solutions for construction projects. Our team of experts can help you design and make custom aluminum extrusions to fit your project's needs. Contact us today to learn more about how aluminum extrusions can help you achieve your sustainability goals.